Ukuthuthukiswa okuqhubekayo kobuchwepheshe bokugcinwa kwemishini yezimboni kule nkathi kuphinde kwabeka izidingo eziphakeme zobuchwepheshe bokukhandaamaphampu egiya le-hydraulic, ingxenye eyinhloko ohlelweni lwe-hydraulic. Njengengxenye ebalulekile yokudlulisa amandla, uma iphampu yegiya le-hydraulic ihluleka, ukusebenza kahle kwalo lonke uhlelo lwe-hydraulic kuzothinteka.

Ngaphansi kwezimo zokusebenza eziphakeme kakhulu zesikhathi eside, amaphampu egiya elisebenza ngogesi angase ahlangabezane nokwehluleka okuhlukahlukene, njengokugeleza okuncishisiwe, ingcindezi engazinzile, umsindo owandayo, njll. Lokhu kwehluleka kuvame ukuhlobene nokuguga, ukungcoliswa noma izinguquko zokuvunyelwa kokulingana ngaphakathi kwephampu. Ukuze kuxazululwe lezi zinkinga, izisebenzi ezinakekela isondlo kufanele zibe nokuqonda okujulile kwesakhiwo kanye nomgomo wokusebenza wamaphampu agiya amanzi bese besebenzisa okufanele.ukugcinwa kwephampu yegiyaamasu.

Isinyathelo sokuqala sokusevisa iphampu yegiya le-hydraulic wukuhlolwa okuphelele nokuxilongwa. Lokhu kuhlanganisa ukuhlola ukubukeka kwepompo ukuze kuqinisekiswe ukuthi zikhona yini izimpawu zokuvuza noma zokulimala; ukulalela umsindo wepompo lapho isebenza ukuthola ukuthi kukhona imisindo engavamile; kanye nokulinganisa ukugeleza nokucindezela kwepompo ukuze kuqinisekiswe ukuthi ziyahlangabezana nezidingo zokusebenza. Ukwengeza, amafutha we-hydraulic nawo adinga ukuhlolwa, ngoba ukungcoliswa noma ukuwohloka kwamafutha ngokuvamile kungenye yezimbangela eziyinhloko zokuhluleka kwepompo.

Isinyathelo 1: Ukuhlola Kokuqala

Ngaphambi kokungena enqubweni yokulungisa, kubalulekile ukuhlola kahle iphampu yakho yegiya elisebenza ngogesi ukuze ubone inkinga ewumsuka. Lokhu kuhlanganisa ukuhlola izingxenye zephampu ukuze zivuze, imisindo engajwayelekile, ukusebenza okuncishisiwe, nanoma yiziphi izimpawu zomonakalo ezisobala. Ukwengeza, ukuhlola izinga loketshezi kanye nekhwalithi kunganikeza imininingwane ebalulekile ngesimo sepompo.

Isinyathelo sesi-2: Ukuqaqa

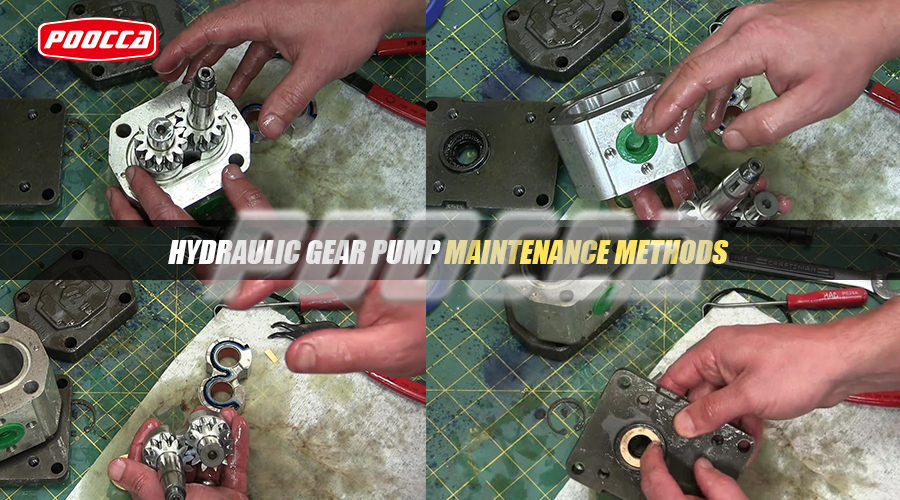

Uma ukuhlola sekuqediwe futhi inkinga isikhonjiwe, isinyathelo esilandelayo ukuqaqa ngokucophelela iphampu yegiya elisebenza ngogesi. Qala ngokunqamula iphampu ohlelweni olusebenza ngamanzi bese ukhipha uketshezi olusebenzisa amanzi ukuze uvimbele ukuchitheka. Susa amabhawodi akhwezayo nokufakwa okubambe iphampu endaweni bese uqaqa ngokucophelela izingxenye zepompo, uphawule ukuhleleka nokuqondiswa kokuhlangana kabusha.

Isinyathelo sesi-3: Hlola futhi Uhlanze

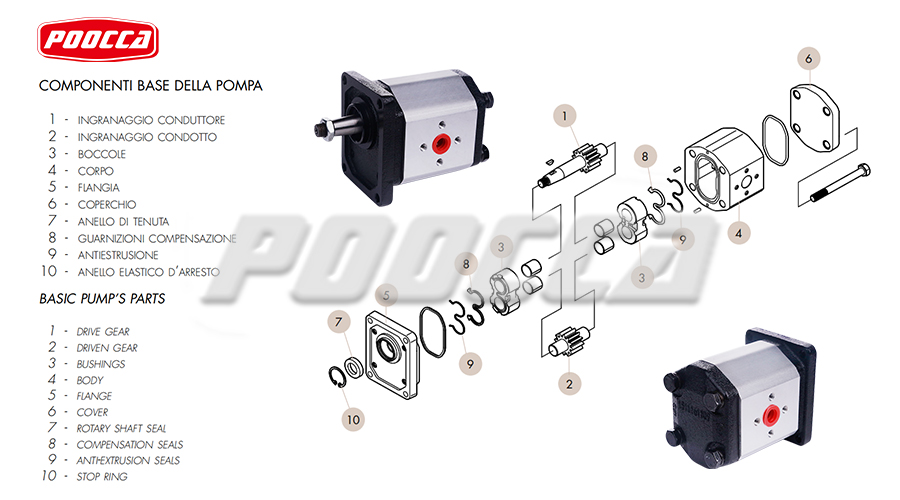

Ngemva kokuqaqa iphampu, hlola ngokucophelela ingxenye ngayinye ukuze uthole izimpawu zokuguga, ukonakala, noma ukugqwala. Naka kakhulu amazinyo egiya, ama-bearing, ama-seal, nezindawo zokuhlala. Faka esikhundleni sanoma yiziphi izingxenye ezilimele noma ezigugile ufake izingxenye ezishintshayo ze-OEM (Original Equipment Manufacturer) ukuze uqinisekise ukusebenza kahle nokuphila isikhathi eside. Ukwengeza, hlanza zonke izingxenye nge-solvent efanelekile ukuze ususe noma yikuphi ukungcola noma imfucumfucu engase ithinte ukusebenza kwepompo.

Isinyathelo sesi-4: Faka esikhundleni uphawu

Ama-Seal adlala indima ebalulekile ekuvimbeleni ukuvuza koketshezi nokugcina umfutho we-hydraulic ngaphakathi kwepompo. Hlola izimpawu zokuguga, ukuqhekeka noma ukuwohloka njengoba lokhu kungabangela ukuvuza kanye nokuncipha kokusebenza kwephampu. Shintshanisa zonke izimpawu, okuhlanganisa izigxivizo ze-shaft, izigxivizo ezithwalayo kanye nezindandatho ze-O, ezinezingxenye ezishintshayo zekhwalithi ephezulu ezihambisana noketshezi olusebenzisa amanzi kanye nezimo zokusebenza.

Isinyathelo sesi-5: Ukuhlola Igiya neBearing

Ukuhlangana kwamagiya kanye nama-bearings kuyizingxenye ezibalulekile zamaphampu egiya elisebenza ngogesi, ezinomthwalo wemfanelo wokudlulisa amandla nokugcina ukusebenza kahle. Hlola amazinyo egiya ukuze uthole izimpawu zokuguga, umgodi, noma umonakalo ongathinta ukusebenza kwepompo nokusebenza kahle. Ngokufanayo, hlola ama-bearings ukudlala ngokweqile, umsindo, noma ama-rough angabonisa isidingo sokushintshwa.

Isinyathelo sesi-6: Hlanganisa kabusha futhi uhlole

Ngemva kokuhlola, ukuhlanza, nokushintsha zonke izingxenye njengoba kudingekile, hlanganisa kabusha iphampu yegiya le-hydraulic ngokulandelana kwe-disassembly. Qinisekisa ukuthi amabhawodi, okokufakwayo kanye nezigxivizo kuqondaniswe kahle futhi kuqiniswe ukuze kuvinjelwe ukuvuza nokuqinisekisa ukusebenza kwephampu efanele. Ngemva kokuhlanganiswa kabusha, isistimu ye-hydraulic iphinde igcwaliswe ngoketshezi olufanele futhi uchungechunge lokuhlola lwenziwa ukuze kuqinisekiswe ukusebenza kwepompo, okuhlanganisa ukuhlolwa kwengcindezi, izilinganiso zokugeleza, nokuhlaziywa komsindo.

Isinyathelo sesi-7: Ukugcinwa Kokuvikela Nokuqapha

Ngemva kokulungisa iphampu yakho yegiya le-hydraulic, sebenzisa uhlelo lokulungisa olujwayelekile lokuvikela ukuze uqinisekise ukwethembeka nokusebenza okuqhubekayo. Lokhu kuhlanganisa ukuhlolwa okuvamile, ukuhlaziya uketshezi kanye nokushintshwa okusebenzayo kwezingxenye ezigugile ukuze kuvinjelwe isikhathi sokuphumula esingahlelelwe kanye nokulungiswa okumba eqolo. Ukwengeza, qapha ukusebenza kwephampu eduze ukuze uthole noma yiziphi izimpawu zokuziphatha okungajwayelekile futhi uxazulule izinkinga ngokushesha ukuze ugweme omunye umonakalo.

Ngemuva kokuthi ukulungiswa sekuqediwe, iphampu yegiya le-hydraulic idinga ukuphinda ihlanganiswe. Phakathi nale nqubo, kubaluleke kakhulu ukuqinisekisa ukuthi zonke izingxenye zifakwe ngendlela efanele futhi zibuyiselwe ezindaweni zazo zangempela. Futhi, buyisela zonke izimpawu ukuze uvimbele izinkinga zokuvuza esikhathini esizayo. Uma ukuhlanganisa sekuqediwe, kubalulekile ukwenza ukuhlola kwesistimu. Lokhu kuhlanganisa ukuqapha amapharamitha epompo abalulekile njengokucindezela, ukugeleza nezinga lokushisa ukuze kuqinisekiswe ukuthi iphampu isebenza kumazinga okuklama.

Okokugcina, izisebenzi zokunakekela kufanele zirekhode zonke izinyathelo ezibalulekile nezinkinga ezitholakala phakathi nenqubo yokulungisa, okuwusizo kakhulu ekunakekeleni kwesikhathi esizayo kanye nokuxilongwa kwephutha. Ngasikhathi sinye, ukugcinwa okuvamile nokushintshwa kwezingxenye ezigqokile kunganweba ngempumelelo impilo yesevisi yephampu yegiya le-hydraulic.

Ngamafuphi, ukugcinwa kwephampu yegiya le-hydraulic kuwumsebenzi osezingeni eliphezulu futhi odinga kakhulu. Ngokuxilongwa okunembile kwephutha, izinqubo ezijwayelekile zokuhlakaza, umsebenzi wokuhlanza ngokucophelela, ukulawulwa okuqinile kwekhwalithi yomhlangano kanye nokunaka imininingwane, izinga lokugcinwa kwephampu yegiya elisebenza ngogesi lingaqinisekiswa, ngaleyo ndlela kuqinisekiswe ukusebenza okuzinzile kwalo lonke uhlelo lwe-hydraulic.

Isikhathi sokuthumela: Mar-27-2024