Amaphampu e-Hydraulic piston angumgogodla wezinhlelo zamanzi asetshenziswa ezimbonini ezahlukahlukene. Kodwa-ke, ukuguga okuqhubekayo kwala maphampu ngokuhamba kwesikhathi kubangela isidingo sezingxenye eziyisipele ukuze zigcinwe zisebenza ngendlela efanele.

Okuqukethwe

1.Isingeniso

2.Izinhlobo zamaphampu e-Hydraulic Piston

3.Izingxenye Ezivamile Eziyisipele zamaphampu e-Hydraulic Piston

4.Ama-Pistons namaPiston Rings

5.Ama-Valves nama-Valve Plates

6.Ama-Bearings nama-Bushings

7.Shaft Seals kanye O-Rings

8.Ama-Gaskets kanye Nezimpawu

9.Izici Zokuhlunga

1. Isingeniso

Amaphampu e-Hydraulic piston asetshenziswa kakhulu emishinini enzima efana nemishini yokwakha, imishini yezimayini, nemishini yezolimo. Lawa maphampu asebenzisa i-piston ephindaphindayo ukuze akhiqize umfutho we-hydraulic, obese usetshenziselwa ukunika amandla amasilinda, ama-motor, nezinye izakhi zama-hydraulic.

Njenganoma iyiphi idivayisi ewumshini, amaphampu e-hydraulic piston ahlangabezana nokuguga nokudabuka ngokuhamba kwesikhathi, futhi izingxenye zawo zidinga ukushintshwa. Ukunakekelwa okufanele kanye nokusetshenziswa kwezingxenye zangempela eziyisipele kungasiza ekuvimbeleni ukuphuka, ukunciphisa isikhathi sokuphumula, nokwelula impilo yepompo.

Ezigabeni ezilandelayo, sizoxoxa ngezingxenye eziyisipele ezibalulekile zamaphampu e-hydraulic piston nemisebenzi yawo.

2. Izinhlobo zamaphampu e-Hydraulic Piston

Amaphampu e-Hydraulic piston ahlukaniswa kabanzi abe yizinhlobo ezimbili ngokusekelwe ekwakhiweni kwawo - amaphampu e-axial piston namaphampu e-radial piston.

Amaphampu e-axial piston anamaphiston ahamba ngokuhambisana ne-axis yephampu, akhiqiza umfutho we-hydraulic. Zivame ukusetshenziswa kuzinhlelo zokusebenza zeselula nezimboni, lapho ukucindezela okuphezulu nokusebenza kahle kuyadingeka.

Amaphampu e-radial piston anamaphiston anyakaza ngaphandle ukusuka enkabeni yephampu, akhiqize umfutho we-hydraulic. Zisetshenziswa ngokuyinhloko ezinhlelweni zokucindezela okuphezulu okufana namadrayivu e-hydrostatic, ukucindezela, namathuluzi omshini.

3. Izingxenye Ezivamile Eziyisipele zamaphampu e-Hydraulic Piston

Okulandelayo izingxenye ezibalulekile eziyisipele zamaphampu e-hydraulic piston adinga ukulungiswa njalo nokushintshwa:

4. Ama-Pistons namaPiston Rings

Ama-piston nama-piston rings yizici ezibalulekile zamaphampu e-hydraulic piston, anesibopho sokukhiqiza umfutho we-hydraulic. Amaphistoni ano-cylindrical noma acijile, futhi ahamba aye emuva naphambili ngaphakathi kwesilinda sephampu ukuze akhiphe uketshezi. Amasongo e-piston afakwe kusiyingi se-piston ukuze avale isikhala phakathi kwepiston nesilinda, ukuvimbela ukuvuza koketshezi.

5. Ama-valve nama-Valve Plates

Amavalvu namapuleti e-valve alawula ukugeleza koketshezi olusebenza ngogesi olungena nokuphuma kusilinda sephampu. Badlala indima ebalulekile ekulawuleni umfutho wephampu nokuqinisekisa ukuthi isebenza kahle.

6. Ama-Bearings nama-Bushings

Ama-bearings nama-bushings asetshenziselwa ukusekela nokuqondisa izingxenye zepompo ezijikelezayo neziphindaphindayo. Zisiza ekunciphiseni ukungqubuzana, ukuguga nokuvimbela ukulimala emgodini wephampu nezinye izingxenye ezibalulekile.

7. I-Shaft Seals kanye ne-O-Rings

Ama-shaft seal nama-O-rings asetshenziselwa ukuvala izikhala phakathi kwezingxenye ezihambayo zephampu kanye nezingxenye ezimile. Zivimbela ukuvuza nokungcola koketshezi, ziqinisekise ukusebenza kahle kwephampu.

8. Gaskets kanye Seal

Ama-gaskets nama-seal asetshenziselwa ukuvala indlu yephampu nokuvimbela ukuvuza koketshezi. Adlala indima ebalulekile ekugcineni umfutho wephampu nokuvimbela ukungcola.

9. Izingxenye Zokuhlunga

Izinto zokuhlunga zisetshenziselwa ukususa ukungcola okunjengokungcola, udoti, nezinhlayiya zensimbi oketshezini olusebenzisa amanzi. Zivimbela izingxenye zephampu kusuka.

Isiphetho

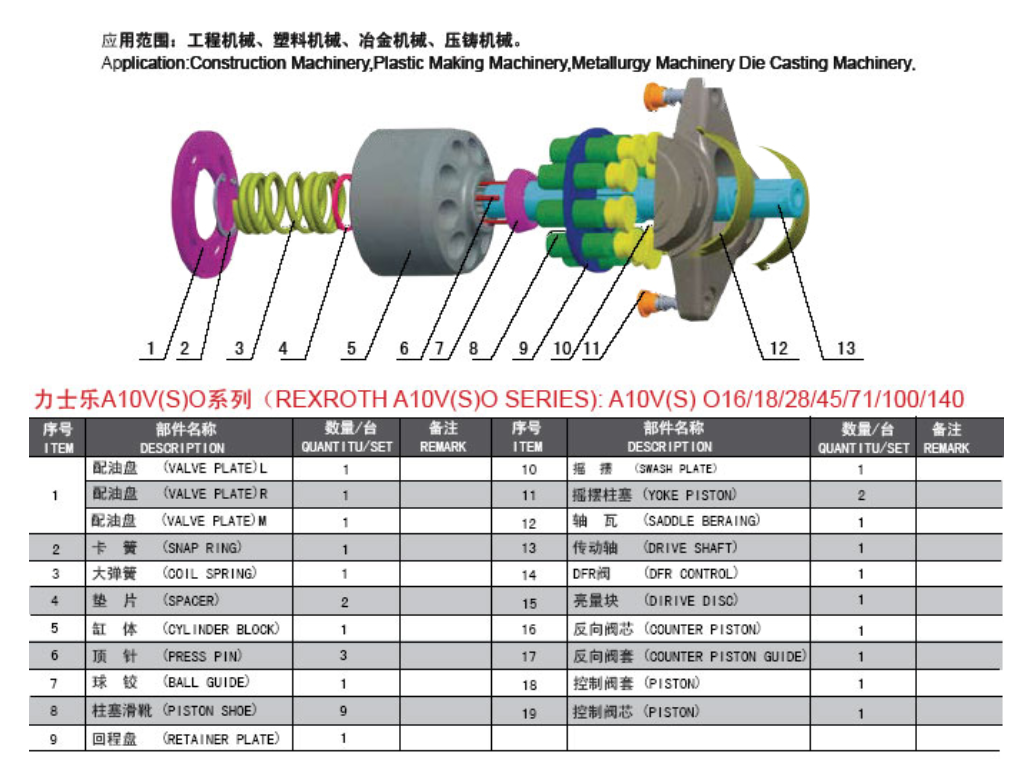

Izesekeli zephampu ye-piston zifaka:

(I-VALVE PLATE(LRM), (INANDATHO), (I-COIL SPRING), (I-SPACER), (I-CYLINDER BLOCK), (IPHINIKHODI YE-PRESS),(IBHOLA UMHLAHLANDLELA),(ISICATHULO SOKUGCINA),(I-RETAINER PLATE),(I-SWASH PLATE),(I-SHASHA PLATE),(I-SHAD ,I-SHADILI) UKULAWULA),(I-DRIVE DISC),(COUNTER PISTON),(COUNTER PISTON GUIDE),(PISTON),(PISTOW)

Isikhathi sokuthumela: Apr-28-2023