Amaphampu egiyaasetshenziswa kakhulu ezinhlelweni ezahlukahlukene zezimboni nezohwebo, okubandakanya amasistimu asebenza ngamanzi, amasistimu okugcoba, nezinhlelo zokulethwa kukaphethiloli. Ukuze kuqinisekiswe ukwethembeka nokusebenza kwayo, iphampu yegiya le-POOCCA hydraulic yenze izivivinyo ezihlukahlukene, okuhlanganisa nokuhlolwa kwezixhumanisi ezintathu.

Kuyini Ukuhlolwa Okuthathu Okudidiyelwe Kwephampu Yegiya?

Ukuhlola okuhlanganisa izinto ezintathu kuyindlela yokulinganisa ukunemba kwejometri nokuqedwa kwendawo yamaphampu egiya. Le ndlela yokuhlola ihlanganisa ukukala amapharamitha amathathu ephampu yegiya - ukuphuma kwe-radial, i-axial runout, kanye ne-perpendicularity phakathi kwegiya ne-shaft axis. I-radial runout iwukuchezuka kwesikhungo segiya ukusuka enkabeni yejiyomethri yangempela, kuyilapho i-axial runout iwukuchezuka kwe-shaft centerline ukusuka enkabeni yejiyomethri yangempela. I-Perpendicularity, ngakolunye uhlangothi, i-engeli ephakathi kwegiya ne-axis shaft.

Kungani Kubalulekile Ukuhlola Okudidiyelwe Okuthathu?

Ukuhlola okudidiyelwe okuthathu kubalulekile ekuqinisekiseni ukusebenza kahle nokuphila isikhathi eside kwamaphampu agiya. Imiphumela yokuhlolwa ingasiza ekuhlonzeni noma yikuphi ukuchezuka kusuka ekunembeni kwejiyomethri okufiswayo nasekuqedeni kwangaphezulu kwephampu yegiya, okungathinta ukusebenza kahle kwayo nokuhlala kwayo. Ngokuhlonza lezi zinkinga, ukulungiswa okudingekayo kungenziwa ukuze kuthuthukiswe ukunemba nokusebenza kwephampu yegiya.

Inqubo Yokuhlola

Ukuhlolwa kwezixhumanisi ezintathu zamaphampu egiya kuhilela izinyathelo ezimbalwa, okuhlanganisa okulandelayo:

Isinyathelo 1: Amalungiselelo

Isinyathelo sokuqala ekuhlolweni kwezixhumanisi ezintathu ukulungisa iphampu yegiya ukuze ihlolwe. Lokhu kuhlanganisa ukuhlanza iphampu kanye nokuqinisekisa ukuthi isesimweni esihle sokuhlolwa.

Isinyathelo sesi-2: Ukulungisa

Ngemva kokulungisa iphampu yegiya, ibe isigxilwa endaweni yokuhlola. I-fixture ibamba iphampu endaweni futhi iqinisekisa ukuthi izinzile ngesikhathi sokuhlolwa.

Isinyathelo sesi-3: Ukulinganisa

Ngaphambi kokuhlolwa kwangempela, isistimu yokulinganisa iyalinganiswa ukuze kuqinisekiswe ukunemba nokunemba. Lokhu kuhilela ukulinganisa izinga elaziwayo nokuqhathanisa imiphumela namanani alindelekile.

Isinyathelo sesi-4: Ukuhlola

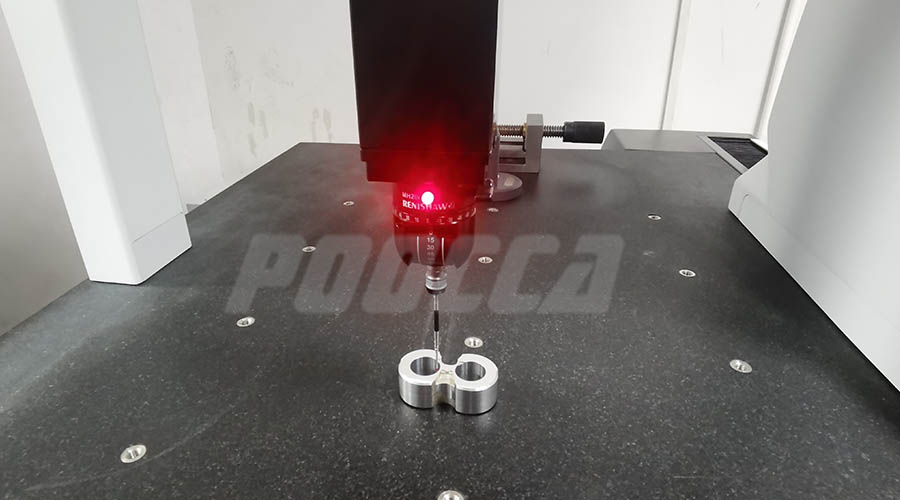

Ukuhlola kwangempela kuhilela ukukala amapharamitha amathathu ephampu yegiya - ukuphuma kwe-radial, i-axial runout, kanye ne-perpendicularity. Lokhu kwenziwa kusetshenziswa umshini wokulinganisa we-coordinate (CMM), othatha izilinganiso eziqondile zephampu yegiya.

Isinyathelo sesi-5: Ukuhlaziya

Ngemva kokuqeda izilinganiso, idatha iyahlaziywa ukuze kutholwe ukuthi ingabe iphampu yegiya iyahlangabezana yini nezicaciso ezidingekayo. Noma yikuphi ukuchezuka kumanani afunekayo kuyahlonzwa, futhi izinyathelo zokulungisa ziyathathwa ukuze kuthuthukiswe ukunemba nokusebenza kwephampu yegiya.

Izinzuzo Three Coordinate Testing

Kunezinzuzo ezimbalwa zokuhlolwa kwezixhumanisi ezintathu zamaphampu egiya, okuhlanganisa okulandelayo:

Ikhwalithi Ethuthukisiwe

Ukuhlola okudidiyelwe okuthathu kungasiza ukuhlonza noma yiziphi izinkinga ngejiyomethri yephampu yegiya nokuqedwa kwendawo, okungase kuthinte ukusebenza kwayo nokuphila isikhathi eside. Ngokuhlonza lezi zinkinga, abakhiqizi bangenza izinguquko ezidingekayo ukuze bathuthukise ikhwalithi nokuthembeka kwamaphampu egiya.

Ukusebenza Kwengeziwe

Isilinganiso esinembile sejiyomethri yephampu yegiya nokuqedwa kwendawo kungasiza ukuthuthukisa ukusebenza kahle kwayo ngokunciphisa ukungqubuzana, ukuguga, kanye nokusetshenziswa kwamandla. Lokhu kungaholela ekongeni kwezindleko ezibalulekile ezimbonini ezisebenzisa amaphampu agiya.

Ukuhambisana Namazinga Omkhakha

Ukuhlola okudidiyelwe okuthathu kuvame ukudingwa ngamazinga nemithetho yemboni, njenge-ISO 1328-1:2013 kanye ne-AGMA 2000-A88. I-Poocca inamathela kulawa mazinga ukuze kuqinisekiswe ukuthi amaphampu egiya ahlangabezana nokucaciswa okudingekayo futhi angasetshenziswa ngokuphepha ezinhlelweni ezihlukahlukene.

Isiphetho

Ukuhlola okudidiyelwe okuthathu kuyisinyathelo esibalulekile ekuqinisekiseni ukusebenza kahle nokuhlala isikhathi eside kwamaphampu agiya. Le ndlela yokuhlola ingasiza ekuhlonzeni noma yiziphi izinkinga ngejiyomethri yephampu yegiya kanye nokuqedwa kwendawo, okungase kuthinte ukusebenza kahle kwayo nokuphila kwayo.

Yonke imikhiqizo ekhiqizwa yi-POOCCA ibhekana nochungechunge lwezivivinyo futhi ingathunyelwa kuphela kumakhasimende ngemva kokuphasa izivivinyo ukuze kuqinisekiswe ukuthi imikhiqizo abayitholayo ingeyekhwalithi ephezulu.

Isikhathi sokuthumela: Apr-20-2023