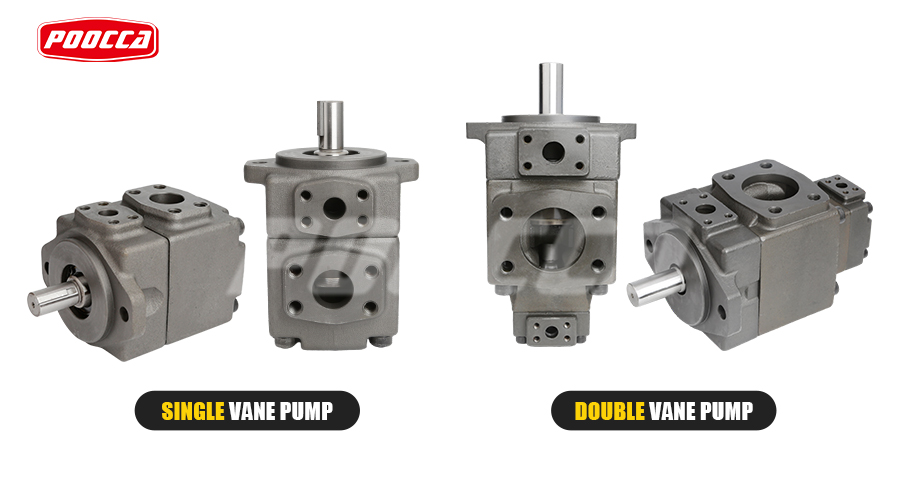

Amasistimu we-Hydraulic awumthombo wezimboni kusukela kwezokukhiqiza nokwakha kuye emkhathini wezindiza nezezimoto. Enhliziyweni yalezi zinhlelo kukhona iphampu ye-vane, edlala indima ebalulekile ekuguquleni amandla emishini abe amandla asebenza ngamanzi. Amaphampu e-vane eyodwa kanye namaphampu ane-double vane izinhlobo ezimbili ezivamile, ngayinye inezinzuzo zayo kanye nezinhlelo zokusebenza. Ngokuhlola umehluko phakathi kwabo, ochwepheshe nabathanda ukuzilibazisa bangenza izinqumo ezinolwazi lapho bekhetha iphampu evumelana nezidingo zabo ezithile.

Iphampu ye-vane eyodwa

1. Idizayini: Iphampu ye-vane eyodwa, njengoba igama liphakamisa, iqukethe i-vane eyodwa ezungezisayo ngaphakathi kwe-eccentric cam cam. Lo mklamo wenza kube lula ukucushwa okuhlangene.

2. Ukusebenza kahle: Amaphampu ane-vane eyodwa aziwa ngokusebenza kwawo kahle kwemishini. Idizayini ye-blade eyodwa ivumela ukungqubuzana okuphansi nokulahlekelwa amandla okuncane ngesikhathi sokusebenza. Lokhu kusebenza kahle kubenza bafanelekele izinhlelo zokusebenza lapho ukongiwa kwamandla kubaluleke kakhulu.

3. Izinga lomsindo: Uma kuqhathaniswa namaphampu ane-vane aphindwe kabili, amaphampu ane-vane eyodwa ngokuvamile asebenza ngokuthula ngenxa yokungqubuzana okuphansi kanye nomklamo olula. Ezinhlelweni lapho ukungcoliswa komsindo kuwukukhathazeka, ukwehlisa amazinga omsindo kungase kube yinzuzo.

4. Ukusebenza kahle kweVolumetric: Lawa maphampu ngokuvamile anikeza ukusebenza kahle kwevolumu ephezulu. Bahlinzeka ngokugeleza okungaguquki futhi okuzinzile kwamafutha we-hydraulic, okubalulekile ekugcineni ukusebenza kwesistimu.

5. Isicelo: Amaphampu ane-vane eyodwa ngokuvamile asetshenziswa kumasistimu adinga amazinga okugeleza aphansi kuya kwamaphakathi, njengamayunithi amancane wamandla we-hydraulic, amathuluzi emishini, nezinhlelo zokusebenza zezimboni ezinezidingo zamandla aphansi.

Iphampu ye-vane kabili

1. Idizayini: Iphampu ye-twin vane inama-vane amabili, ngalinye lizungeza ngaphakathi kweringi yalo yekhamera. Lokhu kusetha kwe-dual-blade kuzivumela ukuthi zibambe amazinga okugeleza aphezulu nezingcindezi.

2. Ukugeleza: Amaphampu angama-twin vane alungele izinhlelo zokusebenza ezidinga ukugeleza okuphezulu nokucindezela, okuwenza alungele imishini esindayo namasistimu anezidingo zamandla adingekayo.

3. Amandla Okucindezela: Ahamba phambili ezinhlelweni ezidinga umfutho ophezulu, njengemishini yokwakha, amasistimu okuqondisa amandla ezimoto, kanye nomshini wokunyathelisa osebenzisa amanzi amaningi. Idizayini ye-dual blade ivumela ukuphatha ingcindezi enamandla kakhulu.

4. Ukukhipha ukushisa: Amaphampu ane-double vane anamandla angcono okukhipha ukushisa ngoba angakwazi ukuphatha ukugeleza okukhulu. Lokhu kunenzuzo ezinhlelweni zokusebenza lapho ukuphathwa kwe-thermal kubalulekile ukuvimbela ukushisa ngokweqile.

5. Ukuhlukahluka: Uma kuqhathaniswa namaphampu ane-vane eyodwa, amaphampu ane-double vane aguquguqukayo futhi angakwazi ukuphatha uhla olubanzi lwezinhlelo zokusebenza. Ngokuvamile zikhethelwa amasistimu adinga ukugeleza okuguquguqukayo nokuphuma kwamandla aphezulu.

Okokugcina

Amaphampu ane-vane eyodwa kanye namaphampu ane-double ane-vane ngayinye inezinzuzo zayo futhi enzelwe izinhlelo ezithile ze-hydraulic. Ukukhetha phakathi kwakho kokubili kuncike ezintweni ezifana nezinga lokugeleza, izidingo zengcindezi, ukonga kwamandla kanye nokucatshangelwa komsindo. Kubalulekile ukuthi ochwepheshe embonini ye-hydraulic baqonde lo mehluko ukuze bakhethe iphampu evumelana kangcono nezidingo zabo ezithile.

Kafushane, amaphampu e-vane eyodwa anikeza ubulula, ukusebenza kahle okuphezulu kwemishini kanye namazinga omsindo aphansi, okuwenza afanelekele izinhlelo zokusebenza ezinezidingo zamandla aphansi. Ngakolunye uhlangothi, amaphampu angama-twin vane, ahamba phambili ekugelezeni okuphezulu, izinhlelo zokusebenza ezinengcindezi ephezulu, okuwenza abaluleke kakhulu emikhakheni yemishini esindayo kanye nezimoto.

Njengoba imboni ye-hydraulic iqhubeka nokuthuthuka, amaphampu e-single-vane kanye ne-double-vane angase athuthuke ekuklanyeni nasekusebenzeni, ngokuqhubekayo andise ububanzi bezicelo zabo futhi athuthukise ukusebenza kahle nokusebenza kwezinhlelo ze-hydraulic ezimbonini ezihlukahlukene.

Isikhathi sokuthumela: Oct-20-2023