Umbuzo wokuthi ingabe iphampu ye-hydraulic ingakwazi ukukhiqiza ingcindezi ibalulekile ekuqondeni umsebenzi oyinhloko wesistimu ye-hydraulic.Eqinisweni, amaphampu asebenza ngogesi adlala indima ebalulekile ekuguquleni amandla emishini abe amandla asebenza ngogesi, ngaleyo ndlela enze ingcindezi ngaphakathi koketshezi.Lawa madivaysi aklanyelwe ukumunca uketshezi olunamanzi futhi asebenzise amandla ukuze aluphushele ohlelweni, okudala ingcindezi enika amandla izinhlobonhlobo zemishini nezinto zokusebenza.Ukuthi kusetshenziswa iphampu ye-piston ephindaphindayo noma iphampu yegiya ethembele kumagiya azungezayo, amaphampu asebenza ngogesi adizayinelwe ukukhiqiza amandla adingekayo ukuze kusebenze kahle uhlelo olusebenzisa amanzi amaningi.

1. Isimiso sokusebenza sephampu ye-hydraulic

2. Uhlobo lwepompo le-hydraulic elidala ukucindezela

3. Izinto ezithinta ukukhiqizwa kwengcindezi kuma-hydraulic systems

1. Isimiso sokusebenza sephampu ye-hydraulic

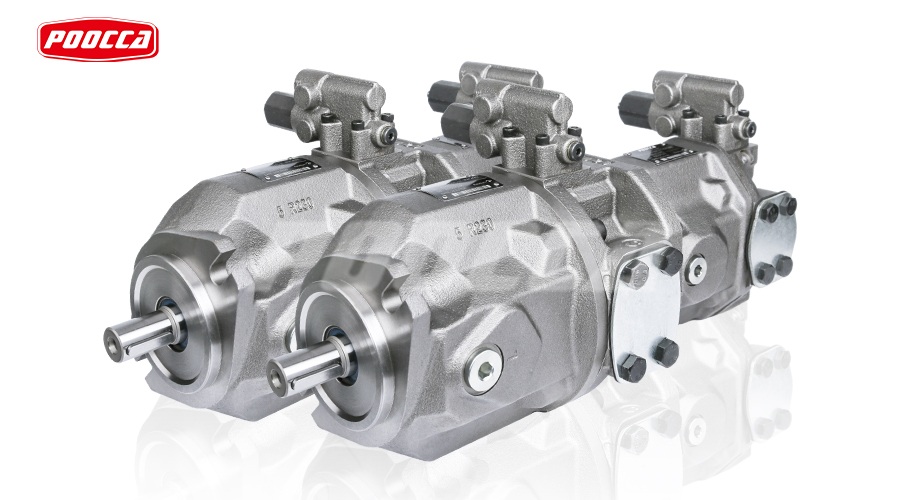

Ipompo ye-hydraulic iyingxenye ebalulekile ohlelweni lwe-hydraulic, umsebenzi wayo oyinhloko ukukhiqiza ingcindezi yokushayela uketshezi ngokusebenzisa uhlelo.Ukuguquguquka kwazo kuzivumela ukuthi zisebenzise izinhlobo eziningi zemishini nemishini, zidlala indima ebalulekile ezimbonini ezifana nezokukhiqiza, ezokwakha nezokuthutha.Lapha sihlola amaphampu amabili avamile we-hydraulic ahamba phambili ekukhiqizeni ingcindezi:

1. Iphampu ye-piston:

Amaphampu e-piston aziwa kabanzi ngokusebenza kahle kwawo ekukhiqizeni ingcindezi ephezulu kumasistimu asebenza ngamanzi.Basebenza ngomgomo wokuphindaphinda, lapho i-piston ihamba phambili naphambili ngaphakathi kwesilinda.Lapho i-piston ihlehla, kwakhiwa i-vacuum edonsa uwoyela we-hydraulic kusilinda.Khona-ke, njengoba i-piston inweba, icindezela uketshezi, iluphoqelele ku-pump outlet futhi lungene ohlelweni lwe-hydraulic.

Enye yezinzuzo eziyinhloko zamaphampu e-piston yikhono lawo lokukhiqiza amazinga okucindezela anele, okuwenza afanelekele izinhlelo zokusebenza ezidinga amandla aphezulu, njengemishini esindayo yezimboni kanye nokucindezela kwe-hydraulic.Ngaphezu kwalokho, amaphampu e-piston aguquguqukayo angalungisa ukugeleza kokuphumayo ukuze alawule kalula amazinga okucindezela ngokuya ngezidingo ezithile zohlelo lokusebenza.

2. Iphampu yegiya:

Amaphampu amagiya angolunye uhlobo oludumile lwepompo ye-hydraulic eyaziwa ngobulula nokuthembeka.Aqukethe amagiya amabili okuxhuma - igiya lokushayela kanye negiya elishayelwa - afakwe ngaphakathi kwekheji yepompo.Njengoba amagiya ezungeza, akha amagumbi adonsa uketshezi olusebenzisa amanzi endaweni yokungena yepompo.Ukuzungezisa bese kuphoqa uketshezi ukuthi lungene endaweni yokuphuma, okudala ingcindezi edingekayo ukuze kusetshenziswe uhlelo lwe-hydraulic.

Nakuba amaphampu egiya engase angafinyeleli amazinga afanayo okucindezela okuphezulu njengamaphampu e-piston, ahamba phambili ezinhlelweni ezidinga ukugeleza okungaguquki nokuzinzile koketshezi.Idizayini yayo ehlangene, izindleko eziphansi kanye nokunakekelwa okuncane kuyenza ifaneleke ezinhlotsheni zezinhlelo zokusebenza zezimboni, okuhlanganisa imishini yokuphatha impahla, amasistimu okuqondisa kanye namayunithi wamandla asebenza ngamanzi.

Ukukhethwa kwepompo ye-piston kanye nepompo yegiya kuncike ezidingweni ezithile zohlelo lwe-hydraulic.Amaphampu e-piston athandwa ezinhlelweni ezidinga ukucindezela okuphezulu nokugeleza okuguquguqukayo, kuyilapho amaphampu egiya ahlonishwa ngenxa yokulula kwawo, ukwethembeka kanye nokusebenza kahle kwezindleko ezinhlelweni zokusebenza lapho ukugeleza okuqhubekayo nokufana kubalulekile.Intuthuko eqhubekayo kubuchwepheshe bepompo ye-hydraulic iyaqhubeka nokuthuthukisa ukusebenza kwalezi zingxenye ezibalulekile, ukushayela ukusebenza kahle kanye nokuqanjwa okusha kuzo zonke izimboni ezahlukene.

2. Uhlobo lwepompo le-hydraulic elidala ukucindezela

Iphampu ye-hydraulic iyisisetshenziswa sokuguqula amandla esiguqula amandla emishini abe amandla omfutho we-liquid.Umgomo wayo wokusebenza uwukusebenzisa ukushintsha kwevolumu evaliwe ukuthutha uketshezi, futhi uthembele esimisweni sokushintsha umthamo ukuze kuzuzwe umsebenzi.Amaphampu we-Hydraulic wonke asebenza ngokususelwa kumgomo wokushintshwa kwevolumu yophawu, ngakho-ke abizwa nangokuthi amaphampu we-hydraulic onyakazayo.

Amaphampu we-Hydraulic ahlukaniswe ngohlobo lwegiya, uhlobo lwe-vane, uhlobo lwe-plunger nezinye izinhlobo ngokuya ngesakhiwo sazo.Ngamunye unezici zabo, kodwa usebenza ngesimiso esifanayo.Ukugeleza okukhiphayo kwepompo ye-hydraulic kungalungiswa njengoba kudingeka ukuze kuhlangatshezwane nezidingo zezimo zokusebenza ezahlukene.

Lapho ipompo ye-hydraulic isebenza, ijikeleza ngaphansi kokushayela kwe-prime mover, okwenza umthamo wokusebenza uguquke ngokuqhubekayo, ngaleyo ndlela wenze inqubo yokudonsa uwoyela kanye nokukhishwa kwamafutha.Izinga lokugeleza kwepompo ye-hydraulic lincike enanini lokushintsha ivolumu yegumbi lokusebenza kanye nenani lezinguquko ngesikhathi seyunithi ngayinye, futhi alihlangene nengcindezi yokusebenza kanye nezimo zamapayipi okudonsa nokukhipha.

3. Izinto ezithinta ukukhiqizwa kwengcindezi kuma-hydraulic systems

Ukukhiqizwa kwengcindezi kuma-hydraulic systems kuthintwa yizici eziningi.Nazi ezinye zezinto ezibalulekile:

**Usayizi womthwalo: Uma umkhulu umthwalo wesistimu ye-hydraulic, uyanda ukucindezela okudingeka ukukhiqizwa.Umthwalo ungaba isisindo sengxenye yemishini, ukungqubuzana, noma okunye ukumelana.

**I-Viscosity kawoyela: I-viscosity kawoyela ithinta izinga lokugeleza kwawo nezici zokugeleza kumapayipi.Amafutha e-viscosity aphezulu azonciphisa izinga lokugeleza futhi akhulise ukulahlekelwa kwengcindezi, kuyilapho amafutha e-viscosity aphansi azosheshisa izinga lokugeleza futhi anciphise ukulahlekelwa kwengcindezi.

**Ubude Bepayipi Nobubanzi: Ubude nobubanzi bepayipi buthinta ibanga nokugeleza kukawoyela ohlelweni.Amapayipi amade nama-diameter amancane akhulisa ukulahlekelwa kwengcindezi, ngaleyo ndlela anciphise ukucindezela ohlelweni.

**Amavalvu nezinye izinto: Amavavu nezinye izesekeli (njengendololwane, amalunga, njll.) zingavimba ukugeleza kukawoyela, kubangele ukwehla kwengcindezi eyengeziwe.Ngakho-ke, lapho kukhethwa futhi kusetshenziswa lezi zingxenye, kufanele kuqashelwe umthelela wazo ekusebenzeni kwesistimu.

**Ukuvuza: Noma yikuphi ukuvuza ohlelweni kuzonciphisa ingcindezi etholakalayo njengoba ukuvuza kubangela ukulahlekelwa uwoyela futhi kunciphise ingcindezi ohlelweni.Ngakho-ke, kubalulekile ukuhlola njalo futhi unakekele isistimu yakho ukuze uvimbele ukuvuza.

**Izinguquko zezinga lokushisa: Ukushintsha kwezinga lokushisa kungathinta i-viscosity nezici zokugeleza zikawoyela.Amazinga okushisa aphezulu akhulisa i-viscosity yamafutha, okwandisa ukulahlekelwa kwengcindezi;kuyilapho amazinga okushisa aphansi encipha amafutha, okunciphisa ukulahlekelwa kwengcindezi.Ngakho-ke, imiphumela yokushisa kufanele icatshangelwe lapho uklama futhi usebenzisa amasistimu we-hydraulic.

**Ukusebenza Kompompo: Iphampu ye-hydraulic iyisici esibalulekile ohlelweni olukhiqiza ingcindezi.Ukusebenza kwepompo (njengokususwa, ububanzi bengcindezi yokusebenza, njll.) kuthinta ngokuqondile amandla okukhiqiza ingcindezi yesistimu.Ukukhetha iphampu efanele yezidingo zesistimu yakho kubalulekile ukuze uqinisekise ukusebenza kahle kwesistimu.

**Ama-accumulators namavalvu okulawula ukucindezela: Ama-accumulators namavalvu okulawula ukucindezela angasetshenziswa ukulawula amazinga okucindezela ohlelweni.Ngokulungisa lezi zingxenye, ukulawula okuphumelelayo nokuphathwa kwengcindezi yesistimu kungafinyelelwa.

Ukukhiqizwa kwengcindezi kuma-hydraulic systems kuthintwa yizici eziningi.Ukuze kuqinisekiswe ukusebenza okuvamile nokusebenza kahle kohlelo, abaklami nabaqhubi kudingeka bacabangele lezi zici futhi bathathe izinyathelo ezihambisanayo zokuthuthukisa nokuphatha.

Impendulo ecacile yombuzo obuzwe ekuqaleni inguyebo - iphampu ye-hydraulic iyithuluzi eliyinhloko lokukhiqiza ingcindezi ohlelweni lwe-hydraulic.Iqhaza labo ekuguquleni amandla ayimishini abe amandla asebenza ngamanzi ibalulekile ezimbonini eziningi, kusukela kwezokukhiqiza nokwakha kuye endaweni yendiza kanye neyezimoto.Intuthuko eqhubekayo kubuchwepheshe bepompo ye-hydraulic iyaqhubeka nokucwenga nokwandisa ukukhiqizwa kwengcindezi, okuholela ezinhlelweni ezisebenza kahle nezisimeme zama-hydraulic.Njengoba imboni ithuthuka, amaphampu asebenza ngogesi ahlala engantengantengi ekubalulekeni kwawo ekunikezeni amandla adingekayo ezinhlelo zokusebenza ezingenakubalwa, egcizelela isimo sawo njengengxenye ebalulekile emishinini yesimanjemanje.

Isikhathi sokuthumela: Dec-06-2023